Benefits

COOLING

SAVE ENERGY BY UP TO 20%

PAYBACK TIME LESS THAN 3 YEARS

HEAT DESTRAT

SAVE ENERGY BY UP TO 40%

PAYBACK TIME LESS THAN 1 YEAR

SUPPLEMENTING AC

SAVE ENERGY BY UP TO 40%

PAYBACK TIME LESS THAN 1 YEAR

VENTILATION

Cooling

A comfortable facility is crucial for optimal productivity. The slow and massive air movement of AirMotion HVLS fans provides a natural, evaporative cooling effect of up to 15°F or more by creating a pleasing, non-disruptive breeze in your facility so the workers (and/or livestock) remain cool, comfortable and more productive in the hot, humid days.

Useful in facilities where air conditioning is not feasible/possible. One AirMotion HVLS fan can replace up to 48 or more high-speed floor or wall fans (often with 1/2 HP motors) and reduce energy usage substantially. What’s more, their near-silent operation makes for a quieter facility environment helping workers concentrate on their work (so, working under the noisy high-speed fans is now a thing of past).

AirMotion HVLS fans eliminate any hot or cold zones in your facility, and maintain a consistent temperature all around, in all seasons.

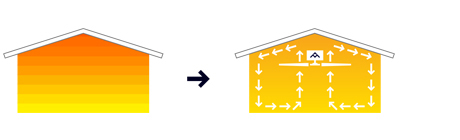

Heat destratification

When heated, air becomes lighter and goes up; thereby stratifying heat-layers, from lower to higher temperatures, in a facility. So, when the air at the roof level is hot, workers at the floor level are not getting adequate warmth. To compensate, you set the thermostat higher, the heater runs too often, and a lot of energy is wasted.

AirMotion HVLS fans provide better heating comfort by mixing the hot air at the roof level with cold air down at the floor level much more effectively to maintain a uniform temperature throughout the facility and reduce up to 40% energy costs (or much more) by reducing heater cycle time (typical payback period is 6 to 24 months). The process is called ‘heat-destratification’.

The fans also save energy by preventing heat loss through facility roofs by not allowing the heat to infiltrate the ceiling/roof material and escape, especially by blowing upwards to capture, move, and mix the many layers of heated air found in high-roof facilities.

Unlike other fans with airfoil or other shapes of blade that are designed to move in only one direction, our symmetrically designed blades are just as effective blowing air upwards as well as down. In most cases AirMotion HVLS fans are 3 times or more effective at moving air upwards than other HVLS fans - something we believe is essential for optimal heat-destratification and air mixing.

Supplementing air conditioning

AirMotion HVLS fans work as an efficient supplement to air conditioning allowing you to set the thermostat several degrees higher for an equivalent cooling effect and reduce HVAC energy costs by up to 40% or more. (The industry rule of thumb says about 3% - 5% energy savings can be realized for every degree of thermostat reduction.) They also minimize the volume of air, and corresponding loss of cool air, that needs to be replaced for adequate ventilation. With new construction AirMotion HVLS fans substantially reduce the cost of ducting, tonnage, and maintenance for air conditioning in large facilities.

Ventilation and IAQ

AirMotion HVLS fans are exceedingly effective at mixing incoming fresh air with the indoor stale air to maintain a refreshing and healthier facility environment by greatly improving ventilation and indoor air quality (IAQ), thus reducing employee turnover, absenteeism, and healthcare costs.

Other benefits

AirMotion HVLS fans reduce damage, waste, and disease while improving floor safety in facilities subject to moisture and humidity issues, thanks to their massive air mixing and movement and related drying effect. They also help keep birds and bugs away reducing all the damages that they can cause.

Applications

There is no end to the many spaces that can benefit by AirMotion HVLS fans, where people work, livestock are housed and fed, and energy is spent on heating, cooling, and ventilating. Some examples follow.

WAREHOUSE AND DISTRIBUTION CENTERS

Includes locations where goods are stored and/or moved around, delivered and shipped, including the DC/wholesale aspect of retail, apparel companies and other entities regardless of their sic code. Key benefits are comfort, energy and cost savings, increased productivity, and reduced product spoilage.

INDUSTRIAL AND MANUFACTURING FACILITIES

Includes factory locations where products are made by people regardless of industry sic code (ranging from boat manufacturers to high tech factories). Key benefits are comfort, energy and cost savings, increased productivity, and ventilation.

AGRICULTURAL OPERATIONS

Dairy, farm, feed, and other food related production or processing situations. Key benefits are human and animal comfort, energy and cost savings, productivity increases, ventilation, and reduced spoilage from humidity and pests.

AUTOMOTIVE FACILITIES

Includes auto dealers, repair, and service. Key benefits are comfort, energy and cost savings, and increased sales and productivity.

MILITARY AND MAJOR AIRLINE HANGARS, TERMINALS, AND AVIATION REPAIR CENTERS

Many government, quasi-government, and commercial carriers opportunities. Key benefits are comfort, energy and cost savings, ventilation, safety, and productivity.

MUNICIPAL

Includes DPW facilities, gymnasiums, and public transportation terminals. Key benefits are comfort, energy and cost savings, ventilation, safety, and productivity.

COMMERCIAL/CONSUMER SPACES

Sports complexes, retail stores, churches, and other locations where the general public may experience the benefits of HVLS fan capabilities. Key benefits are comfort, energy and cost savings, and increased sales and productivity.